Menu

- Our Brochures

For complete information on our services, please download our corporate brochure

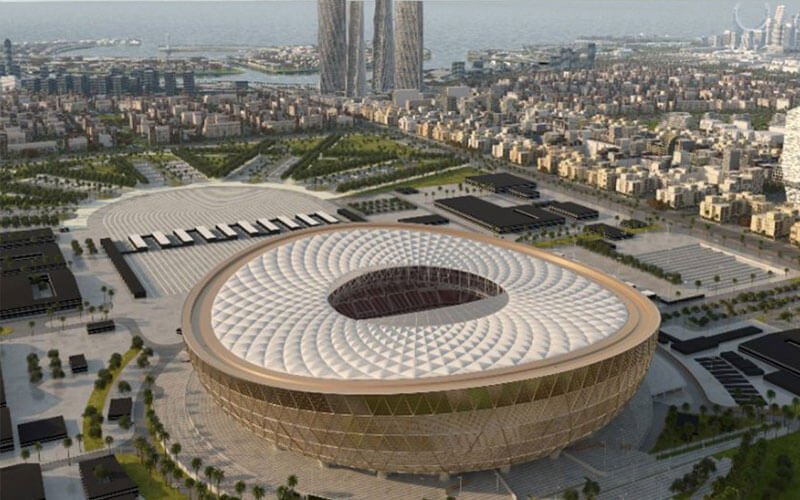

PEB structures are a great option for a variety of sports arenas, offering several advantages:

Structural Repairs:

- Cost-effective: PEBs are generally less expensive to construct than traditional steel or concrete buildings. This is because the components are pre-fabricated off-site, reducing on-site labor and construction time.

- Fast construction: Since the parts are pre-engineered and manufactured beforehand, PEB structures can be erected very quickly compared to traditional methods. This is especially beneficial if you need a new arena quickly.

- Durable: PEBs are made from high-strength steel and are designed to withstand various weather conditions, including heavy snow and strong winds. • Versatility: PEBs can be customized to fit a wide range of sizes and shapes for different sports or event needs. They can also be designed to incorporate features like skylights or clerestories for natural lighting.

- Clear-span interiors: PEBs are ideal for creating large, open spaces without columns or support beams obstructing views. This is crucial for sports arenas where spectators need a clear sight of the field.

Corrosion Protection:

- Coatings: High-performance paints and coatings create a barrier between the steel and the corrosive environment. Different types of coatings offer varying levels of protection depending on the specific needs.

- Cathodic protection: This technique uses an electrical current to make the steel structure the cathode (protected electrode) in an electrochemical cell. This disrupts the corrosion process and protects the steel. There are two main types: o Sacrificial anodes: These are less expensive and typically used for smaller structures. They corrode instead of the steel, but need periodic replacement. o Impressed current cathodic protection (ICCP): An external power source provides the current. ICCP offers more control and is suitable for larger structures or complex geometries.

- Pile Wrapping: Encasing steel piles or beams with materials like fiber-reinforced polymer (FRP) Jackets creates a physical barrier against corrosion and can also add structural strength.

By implementing a combination of structural repairs and corrosion protection strategies, port authorities can ensure the continued safe and efficient operation of their facilities for many years to come.